To View the February 2025 Digital Issue — Click Here

Brad Boner, ASI President

By the time this is printed in the February edition of the Sheep Industry News, the 2025 ASI Annual Convention will be in the books, the Board of Directors will have elected a new officer team to steer the ship and my term as president will be done.

There remains much for each of us to do as we try to secure a five-year renewal of the Farm Bill that includes the Wool Apparel Manufacturers Trust Fund, the Wool Research and Promotion Program, the National Sheep Industry Improvement Center and the Wool Marketing Loan Program. Also, there is lots to do in helping the new administration role back the government overreach that was so prevalent during the last year, including the Bureau of Land Management Conservation Rule and the ban on spring ejector devices for coyote control. And there will be many other items – known and unknown – that will demand our attention.

At the risk of leaving someone out, I would be remiss if I didn’t offer THANK YOU’s in my final column.

First, I would like to thank those folks in other organizations, members of Congress and agencies that ASI works with who have proven to be reliable and trusted allies. As we paddle upstream – sometimes against strong currents – we could not do it without your guidance and support.

We are extremely blessed to have a knowledgeable, intelligent, hard-working staff that care deeply for our industry, and I cannot thank them enough for all they do on a daily basis to secure a future for the American sheep industry. Thank you, thank you, thank you.

I would like to thank the amazing officer team I have had the extreme pleasure to work with. Susan Shultz, Ben Lehfeldt and Joe Pozzi, your passion, knowledge and vision for this industry is unmatched. We have worked closely together, challenging each other and pushing each other to think outside of the box. I will forever treasure our time together and the things we were able to accomplish by being a TEAM.

I would also like to thank the amazing membership of ASI. The passion that exists for this industry among you is an awesome thing to witness. Although we might not always agree on the solutions, I have never once been able to question the fact that each of you LOVES this business and truly wants to make it better and sustain it for the next generation. That is proven to be true by your unwavering willingness to volunteer time and resources to support the industry that has given so much to us.

I would like to express – although inadequately in words – what a tremendous honor it has been for me to serve the members of this great organization. It has been said many times – because it is true – that sheep people are some of the greatest people on the planet.

Last, but certainly not least, I would like to thank my family and employees at home. In my absence they have had to pick up the slack time and time again. It would be impossible to devote the necessary time to this job without their extra effort and support. Until we meet again, keep it on the sunny side.

It’s the start of a new calendar year, still winter but, spring is on its way. At the time of this writing, the U.S. Department of Agriculture’s sheep inventory report has not been released but it will be by the time of publication. So, I’ll leave inventory numbers to the next writer.

But, there remains plenty to examine in the markets between the end of one year and the beginning of the next.

PRODUCTION

Mature sheep slaughter seemed surprisingly large in 2024. Federally inspected slaughter was the equivalent of about 4.3 percent of the ewe inventory in 2024 compared to 4 percent in 2023. That was the largest rate of slaughter as a percent of the ewe flock since 2021. On average in the last decade, that percentage has been about 3.8 percent.

On the lamb and yearling side, federally inspected slaughter totaled 1.75 million head. That was 0.7 percent larger than the prior year. When combined with slightly higher weights in the second half of the year, lamb production was about 2.5 percent larger than the prior year. Greater production likely pressured prices during the year.

Dressed weights exhibited the normal seasonal pattern in 2024, peaking in the spring and declining later in the year. What made them interesting was that during the first half of the year they were below 2023’s weights, but in the second half of the year they were heavier than in 2023. When comparing production between 2024 and 2023, lighter weights helped to offset larger slaughter during the first half of the year while later in 2024 heavier weights boosted lamb production.

PRICES

On the meat side of the market, lamb prices exhibited little of the normally expected seasonality in 2024. The lamb cutout traded between $460 and $480 per cwt. all year until a late slide below $460 in the last couple weeks of the year. Shoulders, racks and loins exhibited the same flat trading pattern. Normally, different cuts experience different seasonality of prices, either driven by holidays – Easter or other religious holidays – or by production patterns. For example, tighter supplies of lamb in late summer, but little of that seasonality materialized in 2024.

Live lamb prices exhibited a much more normal pattern than lamb meat. Although, the range from high to low was larger than average. That appeared to hold for traditional heavier slaughter lambs and lightweight, 60- to 90-pound slaughter lambs. The larger range of prices throughout the year suggests some increase in price volatility compared to past years.

Examining the average, standard deviation, and coefficient of variation as measures of volatility using weekly prices each year from 2020 to 2024 revealed some interesting results. The standard deviation and coefficient of variation of prices in 2024 was not nearly as volatile as in 2022. But 2022 was the year prices collapsed from very high to terribly low levels creating the appearance of more volatile prices.

Price volatility looks a little different depending on the data used. Auction market data for 100- to 150-pound lambs indicates little difference in price volatility measured using the coefficient of variation in 2024 compared to other years since 2020. For 60- to 90-pound lambs, little difference is noted for data from San Angelo, Texas, and Sioux Falls, S.D., auction market reports. However, Fort Collins, Colo., prices indicate a little more volatility in 2024 compared to 2020 to 2023. The USDA/Agricultural Marketing Service 352 national negotiated slaughter lamb report indicates a little less volatility than the last five years, but it is worth noting that much of the data for 2020 was not available due to confidentiality rules.

On balance, there is some truth to the idea of more volatile prices when looking at the range of prices this year. The timing of price movements is likely important as well given buying and selling times. But some simple measures of volatility don’t indicate much change from the past.

TRADE & STORAGE

Imports continued to be above a year ago, adding to lamb on the market. Lamb imports did decline later in 2024 but remained above the prior year. Australian lamb leg prices increased compared to American prices later in 2024, which will likely help to pull back imports.

Relatively lower Australian prices relative to domestic prices certainly boosted imports earlier in 2024.

Supplies of lamb and mutton in cold storage have remained restrained. Reduced stock levels combined with increased domestic and foreign supplies does suggest positive movement of lamb in the market. Although there is some uncertainty in the cold storage data. But, overall, lower cold storage stocks are better for prices.

COMING EVENTS

There are a number of things impacting the lamb market that I am interested in for the new year. The first is the inventory report. Mature sheep slaughter, past lower lamb prices and higher costs would indicate falling numbers. Yet, there are some reasons for expansion that might not be captured by the inventory survey. Increased slaughter might indicate some growth.

I expect prices to exhibit some normal seasonal behavior but if domestic production declines there is some opportunity for higher prices. Retail lamb prices have been competitive – at times – with beef in the past year and high beef prices are likely to continue.

While not directly impacting lamb or meat prices, the discovery of screwworms on a cow in southern Mexico should be of interest. Even though it seems far away, keeping screwworms eradicated in the United States is hugely important for all livestock producers. The ranch level costs of dealing with screwworms would likely be prohibitive.

What happens on tariffs will be an important factor this year. Tariffs on imported lamb should result in higher domestic prices benefiting producers. Yet, higher prices will impact what consumers buy, having an opposite effect on purchases and prices.

The American Lamb Board’s 2025 program includes workshops and summits aimed at equipping sheep producers with the necessary tools and resources to profitably grow their operations. Begin planning your year by discovering more about these upcoming opportunities.

The rapid development of utility-scale solar farms across the country has stimulated a significant need for sheep grazing as a means of vegetation management. There are also increasing opportunities for sheep grazing contracts in wildfire-prone areas and vineyards. Sheep grazing helps to eliminate dried plants that might otherwise become wildfire fuel, and grazing in vineyards and other regions helps clear weeds while reducing or eliminating herbicide use.

ALB’s Targeted Grazing Workshops provide sheep producers a unique chance to learn about these paid grazing contracts, which offer significant potential for expanding the American sheep flock, enhancing the availability and price competitiveness of American lamb.

The 2024 workshops were so successful that six additional workshops are planned for 2025.

“These grazing opportunities offer current and emerging sheep producers the chance to increase their profitability and grow flock numbers,” said ALB Chair Jeff Ebert. “The workshops help producers learn how to take advantage of these opportunities in their area.”

Most three-day events consist of two interactive classroom days, followed by a field day, and cover a range of topics, including vegetation management for solar arrays, vineyards and fire suppression.

The workshops planned for 2025 include: April in California; May in Texas; June in Illinois; August in Maryland; September in Colorado; and October in Kentucky.

The American Lamb Summit is scheduled for July 22-25 at the University of Idaho. This biennial industry event addresses critical strategies to improve the sheep industry’s competitiveness and profitability. The American Lamb Summit seeks to inspire a new level of change and collaboration across all sectors of the American lamb industry as it works to improve competitiveness, product quality, and productivity through increased use of the most efficient, progressive management tools.

Visit LambBoard.com to learn more.

Whether you’re shearing five head or 5,000 head, shearing day is an important time for both producers and their flocks. And even though it happens at least once a year on every wool farm and ranch, it’s easy to overlook the details from one year to the next.

“A year is spent growing the product, while only a few minutes are required to harvest it,” according to the ASI Code of Practice for Preparation of Wool Clips, which is available for download and purchase at SheepUSA.org/shop. “It is in this brief harvest period that quality is often adversely affected.”

With that in mind, here’s a brief overview of how to prepare for the arrival of your shearer.

The first thing you need to do is contact your shearer and set a date for shearing. Keep in mind that nothing is set in stone when it comes to dealing with livestock and weather. Prepare to be flexible as things such as weather, broken equipment and illness can hamper your shearer’s ability to get to your farm or ranch on the designated date. Spring snowstorms make scheduling particularly difficult for shearing crews.

As you await your shearing date, order any needed supplies such as wool packs/bags, clips, markers and health supplies. You should also schedule extra help for shearing day. If your shearer doesn’t offer wool handling/classing services, you’ll want to find someone who can help with that. You’ll also need extra sets of hands to move and pen sheep, as well as a variety of other tasks that will come up on the day.

Larger shearing crews will often bring their own shearing trailers, but producers with smaller operations will need to provide a clean, dry environment for shearing to take place. The area should be large enough for the shearer to maneuver while shearing and easy to sweep so it can be kept clean. Two 4-foot by 6-foot sheets of plywood on flat ground in a covered barn can make an excellent shearing floor for a small flock. Raising the shearing board off the ground in a stable manner will help reduce contamination and make wool handling easier. Sheep should not be shorn on old rugs, carpets or poly tarps. Make sure the area is well lit, and electrical outlets are available within 6 feet of the shearing surface.

In the final days before shearing, sheep should be sorted so they can be shorn in the order of: whiteface (from fine to coarse), black face, colored, and hair and hair-crosses. Sheep can be further sorted by lambs and weanlings, rams, sheep that ran in different conditions, and any sheep that might be sick.

Ideally, sheep would be penned under cover in dry, contaminant-free pens to keep their wool clean and dry as wool should not be shorn while wet. Sheep should be kept off feed and water for approximately 12 hours, depending on age and stage of production.

Why is that important? First and foremost, for the health and safety of both the sheep and the shearer. If the gut of a sheep is full, it can add significant weight to the sheep, placing additional downward pressure on the sheep’s organs when in the shearing position, which causes discomfort for the sheep. This might cause the sheep to kick or struggle, leading to more stress on the sheep and extra work for the shearer. You also want to avoid having sheep urinate or defecate on the shearing surface. In addition to contaminating the wool, this can create a slippery work surface for the shearer.

When the day arrives, shear white sheep first, followed by colored sheep and hair crosses to avoid contamination. Belly wool should be removed from the fleece. Topknots and excess tags should be packaged with the floor sweepings, and any areas of high contamination should be removed from the fleece. Wool should also be skirted and classed and packaged with similar wool if that is advantageous when marketing the wool.

Prepare to provide your sheep with feed and water immediately after shearing. You might also need to provide shelter for the flock if cold, wet weather hits in the days following shearing.

And while the sheep and the wool are the first priority on shearing day, remember to take care of your shearers. Always ensure your sheep are penned and supplies are ready. Providing bathroom facilities, a meal and easily accessible water for them will go a long way toward assuring they return the following year. Remember, shearing is a difficult, physically demanding job and there are fewer and fewer people willing to take it on every year. So, you want to keep your shearers happy.

Additional Resources

Preparing for Shearing: SheepUSA.org/wp-content/uploads/

2022/09/Preparing-for-Shearing.pdf

Preparation Steps for Wool Quality Improvement: SheepUSA.org/wp-content/uploads/2021/11/Prep-Steps-Brochure-Small-Size.pdf

Wool & Pelt Information: SheepUSA.org/researcheducation-

woolpelteducation

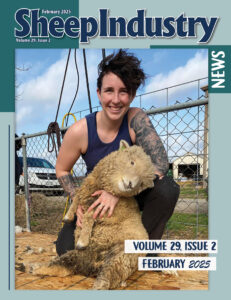

With nearly three million followers on YouTube, you’d be hard pressed to find a more influential advocate for shearing than the ladies at Texas-based Right Choice Shearing. Add in hundreds of thousands of followers on Facebook, Instagram and TikTok and it’s easy to wonder if the two are shearers or influencers. The truth is, they’re both.

“I can’t say that much in my career has ever been planned, and the same goes for social media,” says Katie McRose, who owns and operates Right Choice Shearing with her wife, Darian. “My start was on Facebook, with a modest page with 500 followers, mostly my clients. I would share articles that I had written on scientific papers regarding animal husbandry. I found most of these papers during my animal science senior seminar (at Texas A&M University), where I presented on the effects of shearing on sheep.”

Educator might be a more appropriate description of Katie than influencer. Along the way, that education process crossed the line into entertainment, and the views poured in by the thousands.

“In 2021, physical and mental burnout were just starting to set in. Our schedule was jam packed and it felt like every part of the job was just so stressful,” Katie recalls. “I leaned hard into my desire to educate and began posting Facebook videos of me shearing with write-ups explaining the animal’s behavior. This evolved into TikToks showcasing personalities and satisfying shearing sprinkled with factual knowledge that not only helped educate owners but began combating misinformation held by the general public. After realizing our impact on society’s opinion of shearing, we continued to expand across platforms and rather quickly became the largest agricultural YouTube page in the world.”

The funny thing about that is that Katie wasn’t the best ambassador for shearing early in her career.

YOUTHFUL NAIVETY

Her original, self-taught shearing style wasn’t the traditional Australian method she’s since come to embrace and promote. When she accepted her first shearing job from a Craigslist ad, Katie’s only knowledge of shearing was watching a show goat get trimmed. So, she could be excused a bit for the “choppy” haircuts she and a 4-H friend provided to seven sheep in a four-hour adventure. Their earnings for the day: $35.

“Everything we learned was on the fly. To our knowledge, there were no shearing schools, or even other shearers in the area,” Katie says. “Freshman year of college brought the parting of ways with my initial partner, resulting in Darian joining the crew. She had no experience at the time and was NOT a fan of my sheep shearing method. To be fair, it was quite dangerous. I shore them on their backs but stood between their legs to peel off their fleece in one full piece with minimal second cuts. In this position, I took a lot of beatings from their strong back legs and sharp hooves. Even though I only used Oster Shearmasters and an ugly technique, I could get through a hundred a day.

“Farmers who watched me struggle – but never give up – kept saying there was an easier way to shear sheep, but I had yet to find it. Thankfully, I came across the Texas A&M AgriLife Extension Shearing School in San Angelo (Texas) my senior year of college. Once the instructors – Jake Thorne, Reid Redden and Kraig Chandler – taught me the footwork and the blows, my entire life changed.”

She also used a motorized drop for the first time during the school, which gave her added power in the process. The school was a bit of an eye-opener for Darian, as well.

“When Katie suggested we attend a sheep shearing school our senior year of college, I was still so wary to shear sheep that I conveniently ‘forgot’ to turn in my application by the deadline,” Darian admits. “I did get the chance to sit and watch some of it, though, and the technique and science behind it intrigued me. I applied the next year and learned the Australian method myself, changing our business model a bit as we could now shear side-by-side.”

Darian grew up on a hunting ranch in central Texas as the daughter of a veterinarian. She was exposed to cats, dogs, horses, cattle and a few exotic pets, but had no experience with sheep and llamas before joining Katie’s growing business in college.

“After day one of shearing sheep her method, I was beat to hell and absolutely refused to do it again. She still needed help, so we renegotiated to where I would catch the sheep and Katie would shear them, a rhythm we quickly became comfortable in.”

As they developed their routine and grew the business, the two faced occasional skepticism from farmers and ranchers concerned about their ability to tackle the physically demanding job.

“I’ve encountered many who doubted me because of my build and gender, believing there’s no way I could handle that llama, or that 130-pound Darian could catch their aggressive ram,” Katie says. “That never bothered me either. In my mind, they just gave me the opportunity to impress them even more. My work ethic has shamed many who hold old ways of thinking. Being a two-woman team and handling any job that comes our way really drives home the idea of finesse, technique and determination.”

Certainly, there were some producers who had no choice but to give the two ladies a shot given the lack of shearers in the United States. Katie and Darian made the most of the opportunity, expanding the business to as many as nine states and flocks as large as 250 head while still in college.

“Once we were both shearing in the Australian method, we felt unstoppable in the small flock game,” Katie says. “We could shear a hundred in the morning, a hundred more in the afternoon, and still catch a couple farms of one to ten on the way home.

“In college we serviced 130 farms, but our first year full time we moved that number to 350. The next year we did 475, and in 2020 – when the world was shutting down for Covid – we shore for 575 farms in 100 straight days, with only three days off due to illness. By 2022, I was so ill that I couldn’t keep up with the physical demand of an extremely overbooked schedule.”

SCALING BACK

The two-woman crew made the decision to take a significant step back in recent years. They work only in the Lone Star State now, and limit flocks they shear to 30 head or less. Working with smaller flocks allowed the company to focus on producers who often have the hardest time finding shearers.

“In an average day now, we will get to eight farms, and some days as many as fourteen,” Katie says. “The demand for this skill is so high that truly there’s not much competition. That also means there’s not a lot of help. When shearers retire or become ill or injured, the responsibilities that were on their shoulders have to be carried by their peers who are still able to shear. Darian and I stepped up to carry that weight during Covid.”

Of course, as a shearer, scaling back meant a loss in potential income. But the company’s growing social media presence helped pick up the slack.

“As of now, both facets of my career offer equal support, but fiscal gain was never behind my intentions for creating any video,” Katie says. “That reward I would consider a happy accident, maybe even a little return from karma. I don’t look at my platform as a way to rise through financial ranks, but rather a means to spread knowledge in corners that I otherwise could never have reached.

“Now, my funny videos and examples of animals in severe conditions funds my habit for education. I spend an equal amount of time creating entertainment as well as educational content, which will hopefully give back to my shearing community.”

FINAL THOUGHTS

“Shearing is not the simplest way to make money. It demands high skill, mental fortitude and at least some passion,” Katie adds. “I don’t believe that anyone would go out day after day to sweat, bent over nervous sheep just to make a dollar. There are easier ways. At my first shearing school, there was an open discussion on the public’s perception, and what stuck out the most to me was that these large organizations had the funds to spread misinformation farther than any of the simple sheep farmers could spread the truth.

“When people began watching my videos, they were surprised to see the compassion with which it was done. I spent a lot of my time sharing facts and redirecting misconceptions in the comment section.

“The cool thing was the people I talked to and those that read the comments learned from my efforts. Before I knew what they were, ‘comment warriors’ would jump in and share the information I’d made available to newcomers with repetitive questions and concerns. Now my comment section is mostly filled with love.”

Elaine Palm of West Branch, Mich., was recently hired as the Michigan Sheep Producers Association new executive director. Palm replaces Samantha Bos, who concluded her duties with the organization in January. Bos led the organization for four years.

Palm works alongside her parents – Jim and Sherrie Bristol – on their northern Michigan sheep farm. She purchased her first farm in 2015 to build a second-generation business, adding value to the flock through sales of meat, raw wool and superior genetics. She grew up as an active 4-H, FFA and MSPA youth member and holds a degree from Michigan State University in ag communications. She has an employment history of working with non-profits.

“The strength of this organization is in its people, and we have incredible people and partnerships,” Palm said. “I look forward to building strong relationships and communicating with current and prospective members.”

MSPA President John Schut applauded Palm’s skills and long-term commitment to the organization.

“Elaine brings an extensive history of sheep and agricultural experience to the position, and we are excited to have her serve the organization,” he said. “It is a great time to be involved in the industry and working with professionals such as her.”

Palm praised her predecessors for building a strong foundation of programs including MSPA’s Shepherds Symposium, summer picnic, a blossoming online sheep and equipment auction, quarterly webinars and newsletters, and frequent email blasts focused on training, event updates, and useful industry news and information. She credits previous leadership within the organization for encouraging her toward achieving goals and she is eager for the opportunity to fulfill the same role for producers of all ages.

“I’m looking forward to taking the baton and keep the organization moving forward,” Palm said. “I feel that the timing is right for me, our family and our farm business to step into this role.”

Palm and her husband, Rick, have two young children.

The American Dorper Sheep Breeders’ Society has announced its two nationally sponsored shows and sales. The Mid-America Show & Sale will be held April 10-12, in Duncan, Okla., while the Southern States Show & Sale will be June 26-28, in Cookeville, Tenn.

Located at the Stephenville County Fairgrounds, the Mid-America Show and Sale will showcase more than 250 Dorpers and White Dorpers. The event will kick off with a junior show on April 10 and an annual meeting of the American Dorper Sheep Breeders’ Society.

Single Dorpers and White Dorpers will show on Friday morning with pens of two ewes to follow. South African Philip Strauss will sort the sheep. There will be competitions throughout the day to keep the youth engaged. A skill-a-thon, sales pitch, judging contest and production contest will cap off the youth events. Friday evening will include an Oklahoma-style BBQ with a live band.

Saturday morning will begin with a consignors meeting, followed by an instructional meeting. Sales guests will be able to view lots during the morning hours. The bidding will begin at 10 a.m. and be broadcast live on CCI.

To enter the show and sale, visit Showman.app/#/. If you need assistance, please contact Karla Blackstock at 210-305-2565. Entries will be accepted through March 15 for the Mid-America. Show placings will determine the sale order. For sale order, please visit the association website at DorperSheep.org.

The Southern States Show & Sale will be held at the end of June. Make plans now to attend as 150 of the best lots in the United States will be sold. More information will be available soon.

The American Dorper Sheep Breeders’ Society is one of the fastest growing sheep breeds in the United States. The South African import is versatile with a high parasite resistance.

First-time author and sheep producer Debby Jo Holmquist released her A Shepherdess Beaten But Never Broken: A True Story of Resilience, Triumph and Overcoming Adversity with Grace last month.

The touching memoir chronicles her difficult childhood and how she found solace and comfort in her barn among the animals. Brace yourself for an extraordinary story that speaks to the experiences of those who have faced physical, emotional and psychological childhood abuse and neglect.

For those with dreams deferred by overwhelming challenges and obstacles, this powerful narrative of resilience and perseverance will serve as a lighthouse and inspiration to all who have lost hope. Sharing the intimate details of surviving unimaginable child abuse, the author exemplifies how a determined spirit can overcome the most dire circumstances.

Prepare to be captivated and inspired while cheering her on as she embarks on her journey to freedom. That journey takes her from a dark world of cruelty into the competitive world of producing national championship purebred Dorset sheep. She is, indeed, a shepherdess beaten but never broken.

Holmquist is a nationally certified Polled Dorset sheep judge and has served as a professional judge from coast to coast in North America and Canada. She currently lives in Illinois, surrounded by her beloved Dorset sheep who continue to compete nationally. She has a deep love and understanding for all livestock.

Learn more at DebHolmquist.com.