- December 2011

- Annual Convention Tours and Schedule Information

- ASI Receives Grant

- Conception to Consumption: Producer Focuses on Diversity

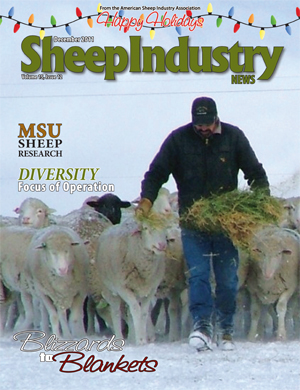

- From Blizzards to Blankets: Mooty Family Revives Historic Minnesota Mill

- Let’s Grow Media Tour Continues in Midwest

- Let’s Grow Topic at Trade Talk

- MSU Receives $743,000 for Sheep Research

- Proper Handling/Management Urged for TX Fine-Wool Sheep

- Research Shows Guard Dogs Relax Sheep

- Vilsack Announces ALB Appointments

Becky Talley

Sheep Industry News Associate Editor

(December 1, 2011) 1865 was a big year for the United States. That year saw the assassination of Abraham Lincoln as well as the end of the Civil War, and as the country began to emerge from the wreckage of the turmoil, Faribault Woolen Mills also opened its doors and began to supply the rebuilding country with quality wool products.

It continued to do so until July of 2009 when financial difficulties, and a growing trend of outsourcing manufacturing, forced the mill to shutter its doors.

But, you just can’t keep a good mill down.

In the face of yet another period where the country is working to rebuild in the midst of tumultuous times, Faribault once again has opened its doors, officially on Sep.15, to provide jobs, bring manufacturing back to the United States, provide markets for wool and continue to produce the quality products it built its reputation on.

Reinvesting, Rebuilding, Revitalizing and … Ice Cream

The mill has new owners and cousins, Chuck and Paul Mooty, to thank for its rebirth.

The Mootys started looking at the mill in April and had a short window to make a decision, as much of the equipment had sold and the remaining equipment was slated to go to Pakistan in a few weeks.

“Neither of us had the knowledge in the industry to make that call quickly, but there are literally a multitude of reasons as to why we felt it was worthy of making the plunge,” says Chuck, chief executive officer (CEO). “There was a beautiful mix of purpose and business. We felt at this stage of our lives we had an opportunity to do something that had a cause that was important – bringing back a community landmark and rejuvenating a community. In this difficult economic environment, we could do our jobs by creating other jobs.”

While other potential buyers of Faribault felt the investment may not be worth trying to deal with overseas competition and outsourcing, the Mootys realized the company had a lot of inherent potential.

First, they felt the long-established Faribault brand was still recognized for the solid performance, quality and comfort of the products it had previously manufactured. In addition, as the mill had not been closed long, the connections and know-how of former associates and employees were still on hand.

“We had the ability to tap the expertise of others, and people we felt comfortable knew the business were able to come back. That reservoir of talent was vital,” he relates, adding, that about 70 percent of the mill’s current workforce are former employees.

In addition, the Mootys felt that it was time to buck the trend of outsourcing manufacturing jobs overseas and demonstrate that the United States can still be a relevant place to manufacture textiles.

“We feel it is important to show how we can be globally relevant as a society, and it’s important that we not lose our manufacturing importance from a global standpoint.”

For Chuck, re-opening Faribault also provides some personal fulfillment as well. In his previous ‘life,’ Chuck was the CEO of International Dairy Queen, the maker of the famous Blizzard and other ice cream treats.

“In my past job, I had a chance to play with an established brand and make it relevant in today’s world. Faribault is an even older brand, and there is intrigue in how we can make this brand relevant today,” he says.

In addition, the mill allows the Mootys to work as a family – Paul and Chuck are business partners, and Chuck’s son, John, is the mill’s marketing director.

“This is a platform for cousins to work together and for my son to work in the business. The family piece really has a meaning.”

Reentering the Market

“We think there is an element that Americana does mean something to the consumer. There is a wave there. The time is right to figure out how we become a local supplier in the United States,” Chuck relates.

The mill is currently up and running with around 35 employees, currently producing blankets, throws and scarves, with the hope to get into other wool products in the future.

“The mill is currently up and running feverishly trying to get products, and the first production run has been using American wool,” he says.

Chuck says that the channels for Faribault products will be in retail, hospitality, health care and government contracting.

“We have been fortunate to be able to tap back into people who knew us for quality. Hospitality is where we have most activity at this point,” he relates, adding that Faribault wool products are currently used in places like the Waldorf Astoria and the Palace Hotel in New York.

In addition, the mill opened its own retail store in November in the Mall of America in order to get a sense of how its products perform from a consumer standpoint.

Overall, the Mootys have confidence that reopening the mill will have an impact on so many levels by creating jobs, promoting U.S.-manufactured textiles, providing a customer for wool producers and continuing the name and products of an icon through adding value to what the mill can offer.

With these goals in mind, Chuck says he hopes to have about 50 employees at year end and to double that by next year.

“Our goal is to create an economically viable model. This thing can perform and we feel good we will prove its ability to perform,” he says. “Secondly, we want to look at how do we elevate our brand so we can be more in a place to produce fashion or accessories, so that the label has a greater meaning as more than a blanket producer. That’s definitely where we hope to go.”