- December 2011

- Annual Convention Tours and Schedule Information

- ASI Receives Grant

- Conception to Consumption: Producer Focuses on Diversity

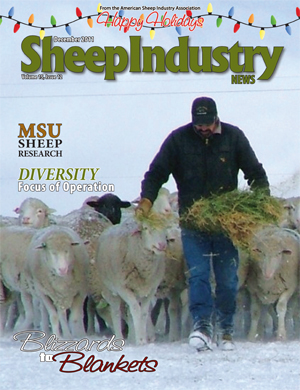

- From Blizzards to Blankets: Mooty Family Revives Historic Minnesota Mill

- Let’s Grow Media Tour Continues in Midwest

- Let’s Grow Topic at Trade Talk

- MSU Receives $743,000 for Sheep Research

- Proper Handling/Management Urged for TX Fine-Wool Sheep

- Research Shows Guard Dogs Relax Sheep

- Vilsack Announces ALB Appointments

Becky Talley

Sheep Industry News Associate Editor

(December 1, 2011) This year has seen many records in the sheep industry; record lamb and wool prices have been cause for celebration for most producers, but unfortunately for some in the South and Southwest, record drought was devastating and a cause for flock dispersal.

This is especially seen in many parts of Texas, which is in the midst of a drought of historic proportions.

Many in the sheep industry stepped up to help those producers who no longer had feed for their sheep, or who could no longer afford to keep the flock, and either worked out pasture leases, flock leases and even outright purchasing those sheep to keep them in production.

Traditionally, Texas sheep are known to have a finer-micron wool than sheep from other regions, so those producers who have bought or are managing these flocks may need to handle this wool differently than their traditional clip to realize the higher price that finer wools can bring.

“The Texas clip has built a good reputation over the last century, at least. A lot of pride was taken in producing fine wool in Texas,” says Will Griggs, manager of Utah Wool Marketing Association.

“At the same time, there are varying levels of quality in Texas sheep, and those quality differences create pricing differences when the wool comes to market each year. To have sheep from Texas doesn’t automatically mean that the wool will be superior to what that producer is already growing on his own pastures,” says Rick Powers, wool trading manager for Lempriere USA Inc., who also ranches in Texas with his family.

Fine wool is in demand, so knowing and keeping the fine part of the Texas clip separate in the wool market is important for the American industry.

“19.0 micron to 20.5 micron is the biggest area of general production in the world. It’s very versatile and it’s a widely consumed micron range. From our standpoint, Texas wools – talking about 12 months shorn, good quality and from good genetics – are part of domestic consumption in the traditional and the emerging military consumption. There is also traditional consumption from companies like Burlington’s worsted fabrics division. For export business, we have ready markets for greasy trading with the Indian and Chinese clients, as well as a ready buyer in Lempriere Australia Pty Ltd for their top-making business,” says Powers.

Griggs agrees that the finer-micron wools are going to continue to be in demand at least in the short term.

“It’s a year-by-year basis, but historically, fine wools have brought more than all others. With superwash and other programs, it looks like more wool may be going into military consumption in the years to come, and we will need that 22 micron and finer wool to meet that possible demand,” Griggs relates.

Changes in Location, Changes in Micron

As producers who bought or are managing these Texas sheep look toward shearing season, an important point to take note of is the affect moving these sheep from the semi-arid climate will have on the fiber micron.

“The sheep-producing area of Texas ranges from land of a semi-arid nature to land with true desert conditions and in general, the semi-arid area forage has a lower nutritional value. Wool is a protein, less protein in-take can result in a finer wool fiber on the animal, but move the same sheep to a protein- and forage-rich environment, and the wool produced from that same sheep will be 1 to 1.5 microns coarser,” says Powers.

So, when these sheep are moved into a wetter, more forage-dense area, their wool fiber will increase in diameter. As always, wool should be objectively measured to properly market and know the wool micron.

“Someone who has Texas sheep may believe they may get a finer micron, but should not be surprised when they send it into the warehouse that it may be 21.5-22 micron. Because the sheep have more nutrition, they will produce a coarser fiber,” Powers adds.

At the same time, due to superior genetics within some Texas flocks, the micron of some of these sheep may not change much, Powers suggests that producers first try to gather information about the original owner of the sheep, and then contact their local warehousemen. The warehousemen have close contact with the U.S. wool trade, who can provide information on a particular clip – the breeding, micron range and what the seller can expect depending on the part of the country the sheep went to.

“My best advice is to find out who you bought the sheep from, take it to your warehouse and let the warehousemen do research and digging to find all the information they can,” says Powers.

Shearing for Success

The goal at this stage is to shear to maximize the value and quality of the fine wool, and as with any shearing, proper handling and preparation is key.

“We would like to see everyone do everything from the code of practice,” says Griggs, such as pulling bellies, skirting the wool and being vigilant not to let polypropylene near the sheep at shearing.

“No poly on any portion of the shearing corral and shearing facility. No poly tarps or poly twine,” he adds. “Insist that the shearing crew look out for black spots, and make sure the bales are packed and marked correctly.”

If possible, the sheep should be kept separate from those with courser micron count, as well as from those sheep with black fiber or hair.

“When you visit with the warehousemen, talk about the possibilities of keeping these sheep separate or keeping them together. You don’t want to mix Texas wool with those sheep of less-quality wool, but if they are already producing a similar micron, you may be able to mix them,” Powers suggests.

However, even if they were run with lesser-quality wool sheep, it is stressed that the finer-wooled sheep should be separated and sheared first, before all others, to avoid contamination from subsequent rounds of shearing. There is a significant price difference between 19.5 wool and 20.5 or 21.5 wools.

In addition, Griggs suggests that producers make sure the wool is graded properly to maximize the profit they may get from the fine wools, and if these Texas wools have been running with other sheep, a grader will be able to pull those fleeces out.

“If you have Texas wool, tell the grader that you have it and there may be a super-fine line. They need to know that we have something possibly extra special in there that needs to be taken care of. They need to really overexploit to the grader that possibility,” Griggs says.

Overall, with proper preparation and a few extra precautions, producers should be able to see the potential of the Texas wools if they came from quality sheep with strong wool genetics. The strong wool market should give all producers incentive to produce the highest-quality wool clip possible.

“Keep the wool coming,” Powers says to all sheep producers. “The market has been down for a few weeks, but we do think there will be a rebound before January, and we expect there will be a strong market when the wool comes off the sheep’s back for 2012.”