- September 2015

- President’s Notes

- Producers Testify in Wyoming

- Let’s Grow Announces Second Round of Funding

- Lone Star State Celebrates Two Anniversaries

- Helle Wins Preliminary Battle in Federal Grazing Lawsuit

- Lamb Jam Master To Be Decided in New York

- Fibrelux Shows Value in Early Tests in San Angelo

- Obituaries

- NSIIC Accepting Grant Proposals

- New Research Journal Article Posted

- Market Report

- Sheep News In Brief

- The Last Word

Fibrelux Shows Value in Early Tests in San Angelo

KYLE PARTAIN

Sheep Industry News Editor

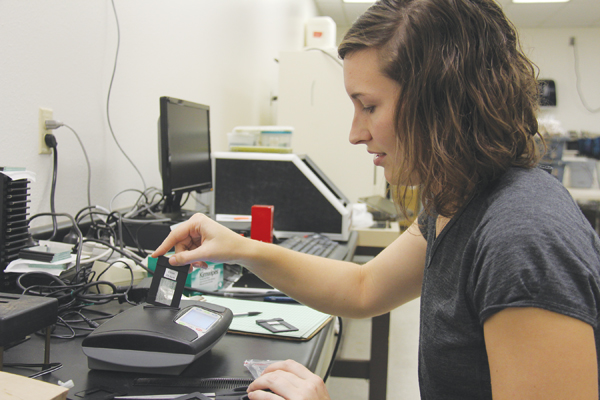

Accurate, portable and (relatively) inexpensive, the Fibrelux Micron Meter might be just what sheep producers need to improve their wool clip, says research scientist Ronald Pope. Ph.D.

Based at the Bill Sims Wool & Mohair Research Laboratory in San Angelo, Texas, Pope and others in the lab have been studying the Fibrelux for a few months now. The machine became available from South Africa earlier this year and comes with a final price tag of about $2,000 – just a fraction of what it would cost to buy similar tools for measuring micron.

While the OFDA 2000 has offered an accurate way to measure micron for years, the $60,000 price put it out of reach for most who work in an around the sheep industry. San Angelo’s wool lab has both the “benchtop” and “suitcase” versions of the OFDA 2000, and thanks to funding from the Wool Council is putting the new Fibrelux to the test as technicians compare readings from the established machines to those provided by the newcomer.

While the OFDA 2000 has offered an accurate way to measure micron for years, the $60,000 price put it out of reach for most who work in an around the sheep industry. San Angelo’s wool lab has both the “benchtop” and “suitcase” versions of the OFDA 2000, and thanks to funding from the Wool Council is putting the new Fibrelux to the test as technicians compare readings from the established machines to those provided by the newcomer.

“We’d like to run about a thousand samples between the two instruments,” said Pope, who believed the lab would meet that goal by the end of last month. “Then, we’ll take that data and start analyzing it to see how they compare in terms of what they are measuring.”

Preliminary tests have shown the Fibrelux to be within the manufacturer’s stated margin of error of plus or minus .4 microns, which is good news for those looking to improve their wool clips. While the Fibrelux is just a measurement tool, there are multiple ways it can help wool producers.

“My personal opinion is that here in Texas it will be used in selection,” Pope said. “Producers can use it going through their rams that they are going to maintain or put back into the stud flock. If you’ve got a ewe flock or stud flock that you are keeping replacements out of, you can go in there and in real time measure those out in the pen and sort them into breeding groups right there.”

The Fibrelux will also prove beneficial in classing wool before, during or after shearing. Because it takes just a minute or two – once you’re proficient with the machine – to get a reading, fleeces can be quickly sorted in a way that might generate more dollars for the clip.

“There are a lot of ranches that might have different breeds that range from a 19 micron to a 23 micron,” Pope said. “Well, if they could break out those 19 and 20 micron fleeces and put those into a sale lot, it makes the clip more marketable. They might get a 10 or 20 percent premium for that wool on the finer end. From that standpoint, it would allow someone who’s more focused on the lamb side to still put wool together in the most marketable manner possible.”

All it takes to get an accurate reading with the Fibrelux is a quick side sample that is combed and inserted into a plastic slide case. Drop it into the small slot atop the machine, press a button and you’ll instantly get a micron reading. Portable and able to run off a battery, the Fibrelux is the best option yet for measuring micron on site.

“With the OFDA 2000, it could be affected by outside conditions,” Pope said. “Wind, dust and direct sunlight – three things that are often present out on the ranch – could create problems and give you some odd readings. Because the Fibrelux is completely enclosed, you don’t have those issues.”

The San Angelo lab has worked with ASI and the Wool Council through the years to lease, purchase and test this valuable equipment. In its efforts to improve and increase wool clip yield within the United States, the Wool Council is certainly interested in putting machines such as the Fibrelux to use throughout the country.

“We’ve got the only one in the United States right now,” Pope said. “But there’s no reason why we couldn’t put dozens of these machines to use. The low cost should allow us to expand the numbers in the years to come. And when it’s more available, then people are more likely to become comfortable with it.”

Pope likens the future of such instruments to the use of scales.

“If I had a warehouse but didn’t use any scales, how many people would bring me their wool?” he asked. “But every warehouse has a scale because they are inexpensive and pretty accurate. This is just another measurement tool, just like a scale. Years ago, classing wool was all subjective. Using tools like the Fibrelux minimizes the guesswork, and it only takes a minute or two to run a sample.”

In testing the Fibrelux in recent months, Pope said there is still room for improvement. Battery life could be better, although users can also plug the machine in to any standard outlet. There’s also no system for keeping data organized. While its sample measurements can be downloaded into a computer, users need to keep hand-written records of tag numbers to identify which sheep go with which samples.

“We’ve passed some of those things along to the company, and I think we’ll see some changes in those areas,” Pope said. “Even if we don’t, there’s no doubt the machine can be a valuable tool when it comes to getting the most out of your wool.”