New Trailer Helps Producers

Generally, the wool from Montana and the Intermountain West is among the best wool in the world. Montana producers will now have access to a shearing trailer worthy of the first-class wool they produce, thanks to grants from ASI and the Montana Department of Agriculture.

The grants provided Mike Schuldt of Miles City, Mont., and Ryan Keyes of Livingston, Mont., the opportunity to create a mobile shearing facility that is focused on bringing optimal value to the grower.

The grants provided Mike Schuldt of Miles City, Mont., and Ryan Keyes of Livingston, Mont., the opportunity to create a mobile shearing facility that is focused on bringing optimal value to the grower.

Unlike the larger sheep producing countries in the world, most American growers do not have dedicated facilities for harvesting their wool. The equipment that the shearer brings to the job often determines the type of preparation that can be accomplished at shearing time. Evolution in the industry has developed a set of market value criteria that rewards growers for proper sorting and preparation at shearing. The market also demands that the wool be packaged in 450- to 500-pound bales for shipping efficiency. Much of the equipment in service today, including shearing trailers and wool presses, predates the current marketing structure.

Today, the industry needs to have the wool prepared for the scouring process at shearing time. This means that the bellies, top knots, crutch wool, leg wool and stained locks must be removed from the fleece at shearing time to retain the highest value. The wool also must be sorted by type so that like kinds can be baled together. This requires that wool handlers have access to the wool as it is being shorn, as well as have the ability to properly pick the fleece from the shearing floor and throw it on a skirting table for further processing prior to baling.

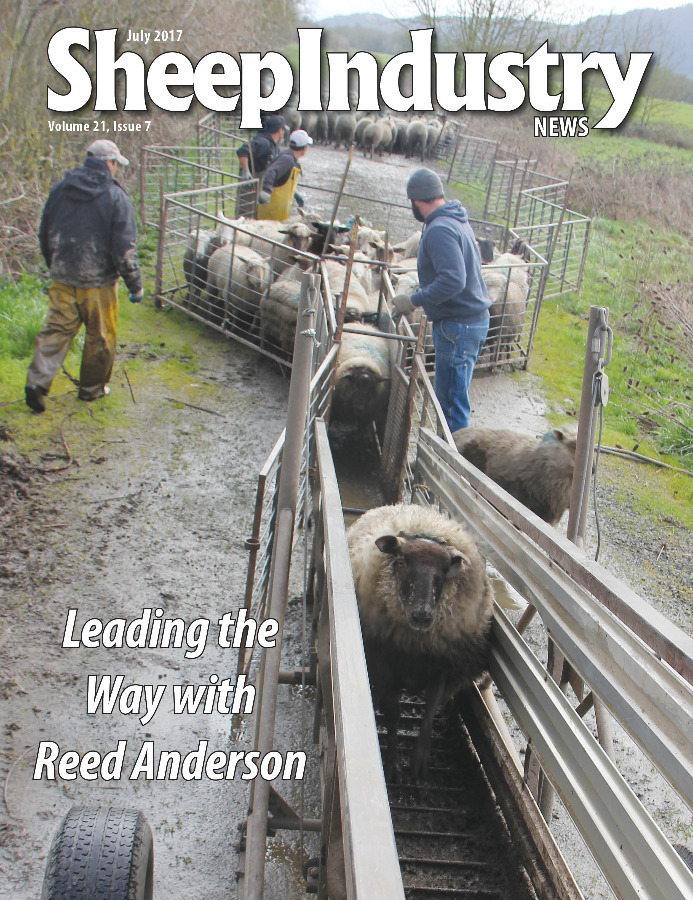

The newly constructed shearing trailer incorporates a number of proven design features, along with some improvements to ensure that the mobile unit allows for the highest quality product to be harvested while providing for the safety of shearers, wool handlers and the animals.

The sheep leave the trailer by way of a ramp under the elevated raceway. This ensures that the workers and sheep are separate to reduce the chance of injury and alleviate stress to the animals. The fold-up side walls are designed to allow the wool handlers easy access to each of the four stations on the shearing floor. These fold up doors only open the lower portion of the wall leaving the upper portion as a safety barrier for the shearer.

Along with improvements in the design of the shearing trailer, the project also provided the means to construct a new wool press that will consistently create an accurate size wool bale. The horizontal design of the baler allows for it to be pulled behind the shearing trailer.

The cost of the materials for this project came to a total of nearly $25,000 and took more than 170 hours of labor for construction of the trailer and wool press. The goal of the project was to create a design that could be emulated by others in the industry.